Loftness Bad Ax (Skid Steer)

|

The new Bad Ax disc mulcher is a highly economical, yet productive skid-steer forestry mulcher built to take on the toughest applications. Featuring direct-drive, the Bad Ax puts 100 percent of its power to the cutting disc, and doesn’t include any pulleys or belts to maintain. It is ideal for land clearing, vegetation control, forest fire prevention and more. |

|

The Bad Ax can cut down trees up to 14 inches in diameter using a 60-inch diameter disc. The fully machined disc is 1.25 inches thick using premium-strength steel, and it contains no welds, so there are no points subject to stress cracking. Additionally, the bolt-on mounts can be replaced in the field without the need for cutting, welding or rebalancing the rotor. The large Bad Ax disc builds up its own inertia during use, pushing its productive force beyond the maximum hydraulic horsepower. This helps it more quickly gather and process vegetation. |

|

The Battle Ax rotor includes built-in depth gauges, which function similarly to raker teeth on chain saws to prevent the attachment from engaging too much material at one time. This unique design is more ideal for managing the amount of material being fed into the attachment than competitive ring-style rotors, which many operators find to be overly limiting — especially with carbide teeth. |

|

The Battle Ax Extreme features the Loftness-exclusive two-stage cutting chamber design, which is capable of processing material more thoroughly than competitive units by cutting material twice. Material is initially cut by the replaceable primary shear bar, located on the rear bumper. Then, an angled deflector drives material back down into the knives for further processing before it is discharged to the ground. |

|

The extreme triple carbide teeth are engineered specifically for the most powerful prime movers. They feature an overlapping cap design that helps prevent the tooth mounts from damage if the rotor is driven into rocks. The teeth are mounted with a single bolt for easy replacement on the jobsite. |

|

Bent-Axis Variable-Speed Piston Motors The Battle Ax Extreme features twin hydraulic motors. These variable-displacement piston motors automatically shift the rotor RPM from the highest speed to a lower range for increased torque as needed. The result is less stalling and a shorter recovery time, helping operators to concentrate on the job instead of power settings and continuous head repositioning. These motors provide a more effective use of power as the head RPM increases under lighter loads, allowing operators to quickly slice through smaller or more flexible growth, as well as when back-dragging material on the ground. As larger trees, trucks and stumps are engaged, the motor increases the drive displacement to increase torque. The motors require 52-108 GPM at up to 6,000 PSI and spin the rotor between 1,400 and 1,900 RPM. |

|

Dual Synchronous Belt Drive The positive drive, cog belt and sprocket design maximizes efficiency and requires less maintenance than other drive types. |

|

The hydraulically actuated door can be closed to trap material for further processing or opened to provide access for felling trees. |

|

The hydraulic cylinder that actuates the door is shielded within the belt cover to help protect it from damage. |

|

Rotor ends are machine turned to mate with close tolerance, machined anti-wrap rings, which minimize debris in the bearing chamber. |

|

A fixed tree-pusher bar is standard on the Battle Ax Extreme mulching head. Constructed with integrated, welded claw hooks, the bar helps push falling trees and brush away from the prime mover, while also allowing them to be properly positioned for efficient feeding into the head. A hydraulically adjustable pusher bar is optional. |

|

All body components are laser cut from premium strength steel. Also, abrasion resistant steel is used in high-wear areas. Customers can choose between the Light series at (5,605 lbs/2,542.4 kgs), or the Heavy series at (6,680 lbs/3,030 kgs), depending on the prime mover/carrier being used. Or, they can select the heavy series, weighing in at 6,680 pounds (3,030 kg), with even more steel for the most demanding applications. |

|

Running the entire length of the attachment, steel deflector chains improve safety by reducing flying debris. |

Today's Hours

Today's Hours

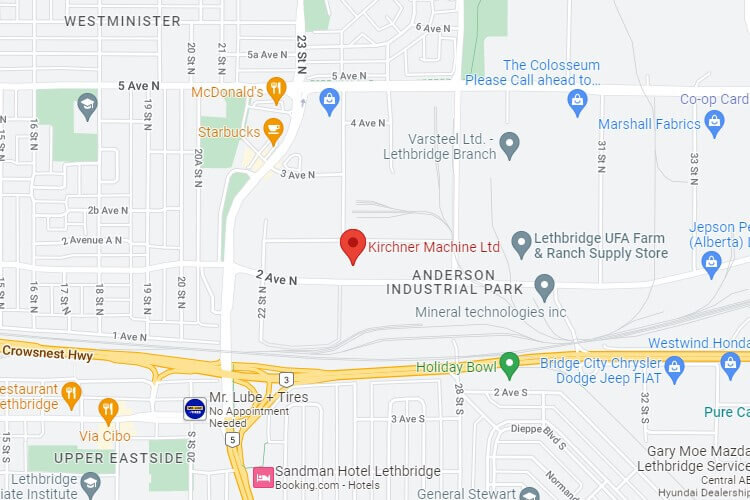

2419-2nd, AVE. N.

2419-2nd, AVE. N.