Loftness 10-Foot System Bag Unloader

-

ID # 27851090

- Back ID:27851090

- Book a Demo

- Get Directions

|

With the capacity to load a 1,000-bushel trailer in about 7 minutes, the Loftness GL System 10 Grain Bag Unloader (GBU 10) outperforms the competition, not only in speed, but in ruggedness and consistency. Stable site-to-site transportation, fast setup, easy operation and straightforward maintenance make it an indispensable part of any grain bag storage strategy. |

|

Features |

|

To achieve load transfer rates of 8,500 bushels per hour, the GBU 10 utilizes a 17-inch main auger made with 1/4-inch flighting. The 50 degree angle of the main auger provides additional height and reach when loading into taller trucks and grain carts.

|

|

The main auger hydraulically folds for easy storage and transportation. |

|

The main auger hinge point is precise and robust. Laser-cut parts, precision welding and spring-loaded self-aligning top bearings ensure the auger shafts align and the male-female drive couplers engage every time. |

|

Designed for unrestricted high-flow performance and longevity, the 10-inch cross augers are driven from the outside end by a drive shaft and chain. |

|

At 16 feet wide, the bag roller has ample room for accepting flattened bags as they are emptied and rolled up. Both ends are capped with 17-inch discs, ensuring that the bag will never overrun the roller. Welded teeth spaced along the entire roller shaft ensure that the leading edge of the bag is captured securely and squarely. |

|

The balanced bag roller assembly pivots and swings from operating to transport position by hand. It locks into transport position with a spring-loaded pin. |

|

The entire roller drive assembly was designed to provide the power and torque needed under extreme loading conditions. Hydraulic motor power is increased and speed is reduced through a reduction gearbox and single chain-drive system. The roller drive pulls the tractor and the unloader into the grain using the bag itself like a tow rope. |

|

An integrated handle, along with stable and robust hinge points, allow the operator to easily and quickly grasp, position and secure the blade for operation or storage. Two cutting positions ensure a positive cut through any bag shape. |

|

Chain Height Adjuster This simple, yet effective, marker chain can be adjusted to gauge the operating height while unloading, regardless of ground conditions. |

|

Built around a 3 1/2-inch shaft and 2-inch spindles, a hydraulically adjustable axle allows the operator to control the height of cross augers inside the bag depending on ground conditions. |

|

Controls are positioned for easy ground access. The four-function hydraulic valve system controls every aspect of the GBU 10. The valve system can easily be converted from open center to closed center. From the control center, the operator can precisely regulate the bag roller speed, adjust the axle height and retract or extend the hinged main auger. |

|

The GBU 10 drivetrain system starts with a shear bolt protected Walterscheid W2400 series PTO shaft. There is a hinged shield that folds up to access the PTO shear bolt for easy replacement. |

|

Operator can simply disengage the roller drive by hand and bag can then be rolled off the bag roller tube. No tools needed. |

|

Power to the main auger and cross augers is delivered through the PTO and transferred through the U.S.-made gearbox to a No. 80 chain drive oil bath coupling system. This provides unsurpassed reliability to both auger systems. |

Today's Hours

Today's Hours

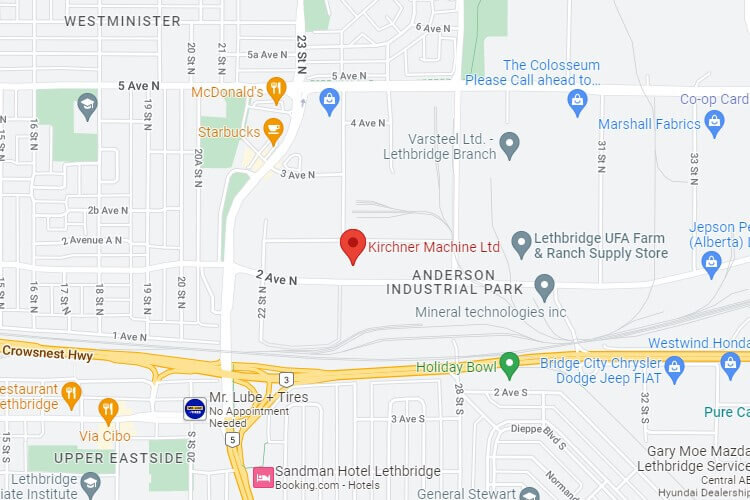

2419-2nd, AVE. N.

2419-2nd, AVE. N.