Loftness Battle Ax (Skid Steer - S Series)

|

The Battle Ax delivers a refined and balanced design that’s unmatched by competitive mulching head attachments. Quite simply, there is no vegetation management tool on the market today that is more durable, more efficient or more versatile than the Battle Ax. |

|

Maximum Efficiency for Vegetation Management Professionals: The new 17-inch-diameter Battle Ax rotor features built-in depth gauges, which function similarly to raker teeth on chain saws to prevent the attachment from engaging too much material at one time. This unique design is more ideal for managing the amount of material being fed into the attachment than competitive ring-style rotors, which many operators find to be overly limiting. It has also proven to perform better with both Quadco blades and carbide cutting teeth. |

|

A One-Two Punch:

|

|

The Battle Ax rotor includes built-in depth gauges, which function similarly to raker teeth on chain saws to prevent the attachment from engaging too much material at one time. This unique design is more ideal for managing the amount of material being fed into the attachment than competitive ring-style rotors, which many operators find to be overly limiting. It has also proven to perform better with both Quadco blades and carbide cutting teeth. |

|

The Loftness exclusive two-stage cutting chamber is capable of processing material more thoroughly than competitive units by cutting material twice. Not only does this allow faster decomposition, but it also results in a nicer looking end product. The primary shear bar is adjustable, so the clearance can be narrowed or widened depending upon the desired material size and production rate. From here, the partially reduced material passes smoothly to the secondary cutting chamber behind the front bumper, where it’s processed further before being discharged toward the ground. |

|

Unlike competitive horizontal drum mulchers that use hydraulic doors to help reduce material, the Battle Ax is engineered to process material more completely without a door. Its distinguishing body shape and hitch angle allow the Battle Ax to be rolled back to expose the knives when cutting trees. Tilting the head forward while backing up pulls downed material against the shear bar for more efficient cutting, which produces finer particle sizes. A second recutter bar at the discharge reduces material further and directs it to the ground. |

|

The Quadco knives or carbide cutting teeth are mounted to the rotor with a single bolt. They can be easily reversed, replaced or removed on the jobsite using a common hex socket. |

|

This exclusive tooth arrangement ensures single-tooth contact with the work surface at all times while maintaining optimal rotor balance. |

|

To achieve below grade mulching, the skid shoes can be adjusted from 0.5 inches to minus 1.5 inches. |

|

Constructed with integrated, welded claw hooks, the bar helps push falling trees and brush away from the power unit, while also allowing them to be properly positioned for efficient feeding into the head. |

|

Rotor ends are machine turned to mate with close tolerance, machined anti-wrap rings, which minimize debris in the bearing chamber.

|

|

The positive drive, cog belt and sprocket design maximizes efficiency and requires less maintenance than other drive types. |

|

A high-pressure relief valve protects the Battle Ax from pressure spikes at the source. It also includes an anti-cavitation shutdown circuit. |

|

An integrated PSI gauge that monitors the hydraulic load is positioned for easy viewing from the skid steer cab. Keeping the Battle Ax at the optimum hydraulic load allows for peak performance throughout an application. |

|

All body components are laser cut from premium strength steel. Also, abrasion resistant steel is used in high-wear areas. |

|

Running the entire length of the attachment, steel deflector chains improve safety by reducing flying debris. |

|

The Battle Ax is designed for maximum visibility from the skid steer cab, which increases safety, productivity and efficiency.

|

|

The universal mount allows the Battle Ax to be easily used with any skid steer brand or model. |

|

Hoses are right sized and routed to reduce the chance of binding, yet are long enough for a full range of motion without damage. Hoses are included, couplers are not. |

| Model | 61 | 71 |

|---|---|---|

| Cutting Width | 61" (1.55 m) | 71" (1.8 m) |

| Overall Width | 76.2" (1.94 m) | 86.2" (2.19 m) |

| Number of Teeth | 30 | 36 |

| Weight (without mount) | 2,500 LBS (1,134 kg) | 2,700 LBS (1,225 kg) |

| Crated Weight | 2,725 LBS (1236 kg) | 2,925 LBS (1327 kg) |

| Hydraulic Horsepower Range | 50-120 Hydraulic HP | 50-120 Hydraulic HP |

| Fixed-Displacement Gear Motor | Up to 4,300 PSI - 28-40 GPM | Up to 4,300 PSI - 28-40 GPM |

| Variable-Displacement Piston Motor | Up to 6,000 PSI - 32-45 GPM | Up to 6,000 PSI - 32-45 GPM |

Today's Hours

Today's Hours

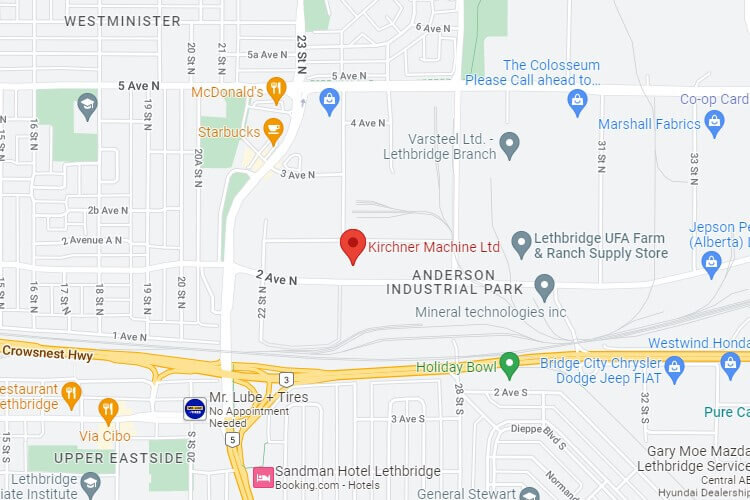

2419-2nd, AVE. N.

2419-2nd, AVE. N.