Loftness 10-Foot System Auger

-

ID # 27851088

- Back ID:27851088

- Book a Demo

- Get Directions

|

Every aspect of the GL System 10 Truck Auger has been designed and engineered to make grain bagging operations more efficient and productive. Perfectly matched for GBL 10 and XLB 10 grain bag loaders, it is a powerful system that is unrivaled in the grain bagging industry. And with a transfer rate of 11,900 bushels per hour, trucks can dump in plenty of time to catch the next load. |

|

Features |

|

The swing hopper is the key to successful truck unloading. Twin 7-inch diameter pan augers move grain quickly from the truck's discharge into the 13-inch diameter swing auger. |

|

The hydraulic-drive hopper wheels are used to move the swing hopper into position under the truck's discharge. The traction tires are foam filled to eliminate air loss from bead failure. |

|

The hopper lift is used to apply down pressure to the drive wheels when positioning the swing hopper. The wheels are then hydraulically lifted off the ground to allow the hopper to rotate on the skid plate. The drive wheels can be lowered to the ground to reposition the hopper while dumping, if needed. |

|

Free-wheeling, rigid gage wheels are adjustable for hopper height control. Solid rubber tires support the far end of the hopper when swinging under the truck's discharge. The swing hopper is designed to rotate under the truck's discharge as the bag loader advances. The skid plate in the center of the hopper helps provide a pivot point for rotation. |

|

The hydraulic control valve is located on the swing hopper auger. The operator has excellent visibility and control when positioning the swing hopper under a moving or stationary truck. |

|

The articulating 13-inch diameter swing auger provides easy reach and positioning control when aligning the hopper under the truck's discharge chute. When the job is done, the same pivoting allows the hopper to swing out of the way. |

|

The high-speed, 13-inch diameter main stationary lift auger moves grain into the hopper of the bag loader. |

|

The backbone of the swing auger/hopper system, the 13-inch diameter transition auger delivers grain to the pivot point over the base of the main auger. |

|

The swing hopper and auger are easily winched up into transport position with a cable/pulley system. Transport chains are deployed once the hopper is in position. Cable tension is then released for transport. |

|

The hopper transport winch is easy to reach from ground level. It is hand operated for years of trouble-free service. Electric or hydraulic operated winches are optional. |

|

The massive all-welded steel hitch is designed to support the drive system and augers. The hitch also carries the weight of the swing hopper when in transport configuration. There is a heavy-duty jack to support the 1,800-pound tongue weight. |

|

The shear-bolt protected drive train will power the entire machine. The transfer case divides the power to drive the truck auger and GBL 10. This gearbox reduces the 1,000 RPM PTO speed to 540 RPM to drive the swing auger and the main tube auger. |

|

The industry-proven transfer case gearbox splits the drive power between the swing hopper system and the main auger. When loading directly into the bag loader's main hopper with a combine or cart, the power to the swing auger and main auger can easily be disconnected by removing a short PTO shaft. No tools required. |

|

The power is transferred and split from the PTO shaft to the transfer case and to the bag loader drive via a heavy-duty No. 60 double chain drive system. Chain drive shafts are supported by opposing dual greaseable bearings. An easy-to-open panel gives access to all of the drive system components.

|

|

Use of industry standard, easy-to-get replacement parts reduces downtime during your critical harvest window. Standard nonproprietary bearings, chains and U-joints are available at most fleet or auto parts suppliers. |

Today's Hours

Today's Hours

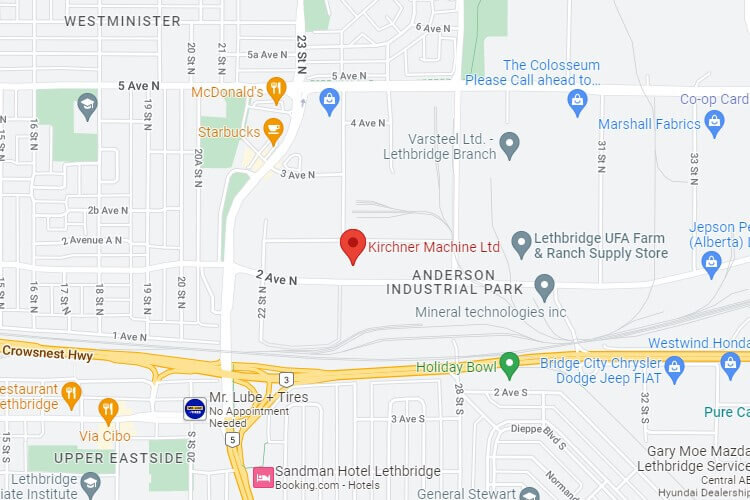

2419-2nd, AVE. N.

2419-2nd, AVE. N.