Loftness 10-Foot Bag Loader

-

ID # 27851086

- Back ID:27851086

- Book a Demo

- Get Directions

|

The Loftness GL System 10 Grain Bag Loader (GBL 10) is a perfectly balanced and controlled workhorse. All across North America, millions of bushels of grain have been loaded and stored because of its ease of use and rugged reliability. It can load a 10-foot x 300-foot grain bag in just over 30 minutes. That's about 13,000 bushels. Every feature of the GBL 10 is designed to help achieve controlled and predictable results, load after load. |

|

Features |

|

|

|

Complementing the precise brake pressure control system are large 12-inch diameter disc brake rotors and calipers. Used in the automotive racing industry, these brake components were chosen for their performance, high degree of reliability and availability. They feature a new easy-to-bleed system. |

|

Maintaining control and position with the terrain is achieved through huge 12.5L 15-inch SureGrip chevron-style traction tires. |

|

The 8-foot by 8-foot hopper is an easy target to hit, helping reduce spillage. It can be loaded from either side or from both sides simultaneously. The hopper is all-steel construction and can take the bangs and dings of in-field use. |

|

The design of our main 20-inch discharge auger is optimized for maximum performance with 1/4-inch thick abrasive resistant steel flighting for long life. During operation, significant directional axial thrust loads are produced against the bearings. Loftness engineers designed the step-down shaft to properly offload these longitudinal forces. |

|

Proper grain distribution in conjunction with smooth and flawless bag feed is the starting point for precise control and nonstop operation. The one-piece tunnel is designed to distribute grain evenly throughout the profile of the bag. |

|

The bag is lifted from ground level into position with the touch of a button using an electric winch. The operator can stand next to the cradle while operating for precise control. After the bag is loaded, the cradle conveniently folds up and stores inside the tunnel. An anti-slip ladder makes perfect bag placement possible. |

|

Installing the bag on the loader is made easy by the cradle's 4,000-pound industrial-grade electric winch. Lifting the bag from ground level to the top of the tunnel is done with the push of a button, courtesy of a wireless remote that comes standard. |

|

The bag pan is lowered to install the bag into position around the tunnel. Once positioned, the bag pan is then raised into the proper operating position to support the bottom of the bag during filling. The bag pan can be fine-tuned by adjusting the turnbuckle. |

|

Industry standard, easy-to-get parts reduce downtime during your critical harvest window. Standard nonproprietary bearings, chains, U-joints and brake system parts are available at most farm, fleet or auto parts suppliers. |

|

The power is transferred from the PTO shaft to the bag loading auger via a heavy-duty #80 chain-drive system. Chain drive shafts are supported by opposing dual greaseable bearings. An easy-open panel (no tools required) offers access to all drive system components. |

|

Power to the drivetrain is delivered through a Walterscheid W2400 Series extra-long shaft that is protected by an easily accessible shear bolt. Power is delivered to the discharge auger shaft by a heavy-duty chain. |

|

The hydraulic lift system is designed around a heavy-duty axle and is powered by dual 4-inch by 8-inch hydraulic cylinders. |

|

The single most important GBL 10 feature is the brake control system. Brake pressure is applied to both sides simultaneously through a rotary hand wheel that controls the master brake cylinder. Pressure is displayed via a large liquid-filled pressure gauge mounted next to the control wheel. |

Today's Hours

Today's Hours

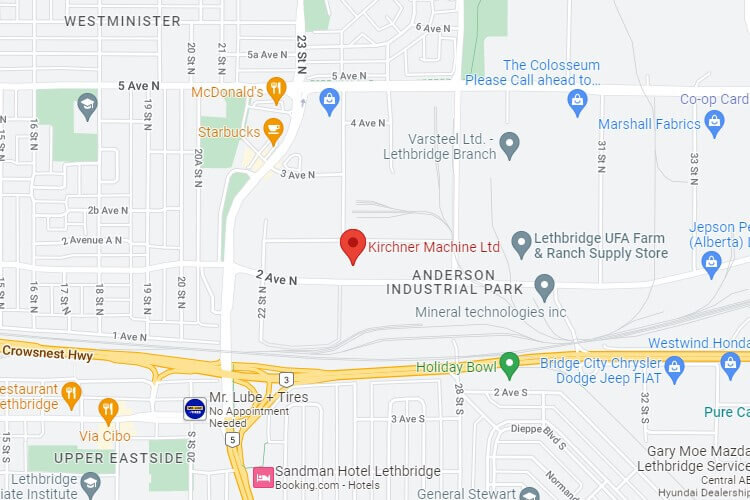

2419-2nd, AVE. N.

2419-2nd, AVE. N.